Hospitals

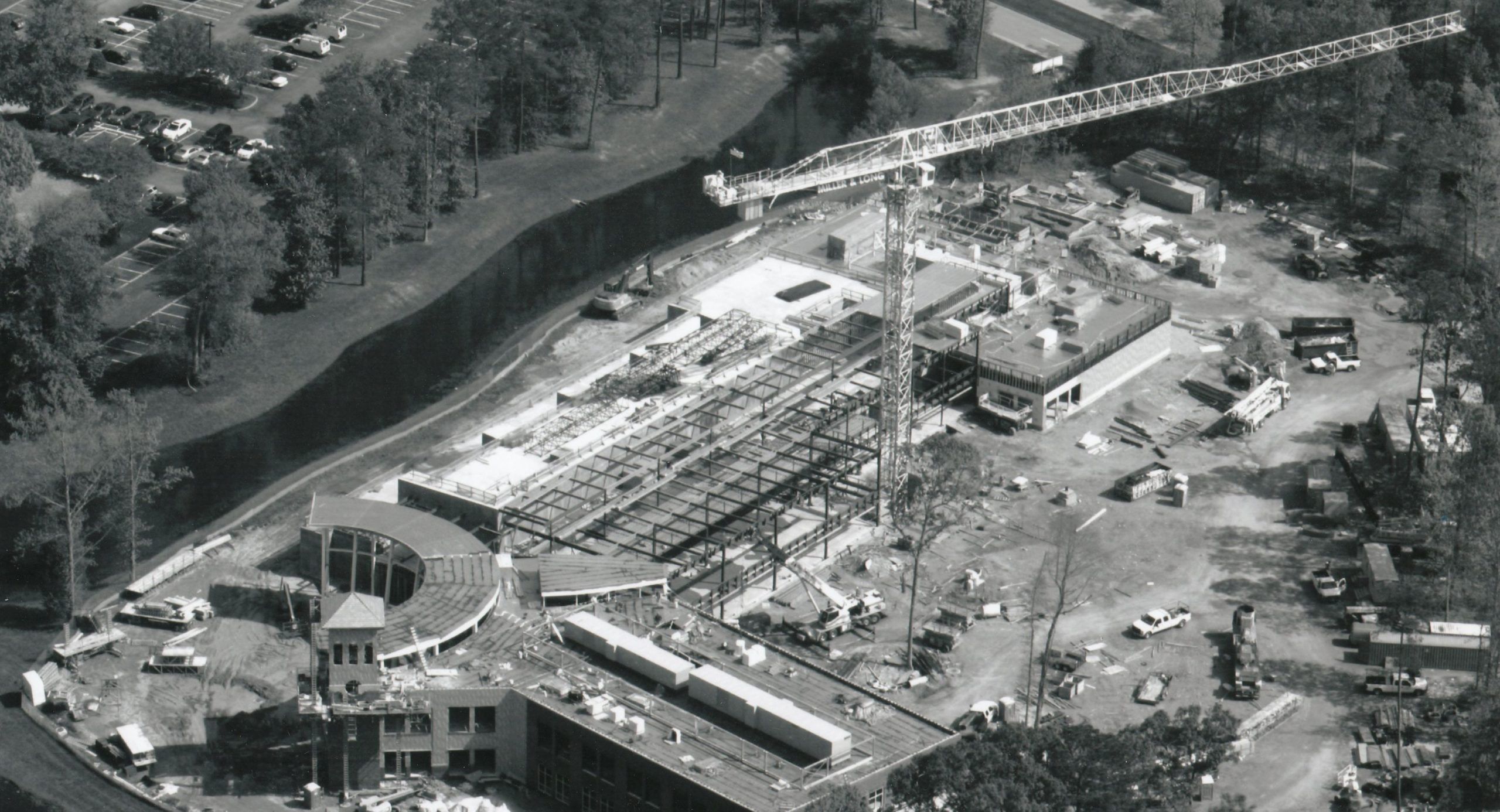

Hampton University Proton Therapy Institute

The structure includes a cast-in-place vault that houses the proton accelerators that are crucial to the Institute’s work. Miller & Long poured and formed the 6’ thick walls and 7’ deep slabs necessary to provide the shielding and contain the ionization radiation that is a byproduct of the accelerators.

Details

Longer cure times – large concrete pours generate considerable heat during curing. To enable sufficient compressive strength and to accommodate the temperature sensitivity, careful attention was given to not exceed a 35-degree heat differential requirement. The concrete cure required 58 days compared to the typical 28 days.

Special mix designs – to not compromise the concrete curing process, the longer concrete curing time required special mixes that could accommodate a slow ambient temperature and ensure temperatures stayed within tolerance. To accomplish this, we modified our slag and admixtures to produce a low heat-generating concrete mix with a slower curing time.

Customized framing design – this was required to accommodate the unique vertical and horizontal elements and the 6’ thick walls and 7’ deep slabs. Nearly three times the amount of framing materials was required to help contain and support the walls and slabs.

summary:

Category: Hospitals

Location: Hampton, VA

General Contractor: Armada Hoffler Construction

Delivered: 2008

CY: 16,500

SSFS: 27,000

Featured Projects

1900 Reston Station Plaza

Capital One Headquarters